Coating Place, Inc. has been Wurster coating since 1976. Our experience with Wurster coating along with our highly qualified R&D and production personnel help us guarantee our customers optimal services to meet their capacity, efficiency, and quality needs.

We developed our state-of-the-art fluid bed microencapsulation Wurster coating units using Dr. Dale Wurster’s original intellectual property and prototype equipment. Over time, we’ve enhanced the design with proprietary fluidization plates and nozzles, setting us apart in the industry. These innovations, coupled with our feasibility and product development services, ensure top-tier quality in the Wurster fluid bed coating sector.

Our proprietary technology provides unmatched linear scalability, recognized by the FDA, allowing seamless transition from research to production without costly testing. Coating material is applied with precision using our unique nozzles and customizable plates, ensuring consistent results across all scales.

Capabilities

With 20 advanced Wurster units across two facilities, we accommodate projects from 0.05 to 800 L (0.01 to 800 kg).

Research Units

Model 400: 2", 4", or 6" plates (batches 0.05 - 8 L)

Model 600: 2”, 4'“, 6”, or 9” plates (batches 0.05 - 20 L)

Model 900: 4”, 6", 9", or 12" plates (batches 0.2 - 40 L)

Production Units

Model 1800: 12" or 18" plates, single nozzle (batches 10 - 90 L)

Model 3200: 32" plate, 3 nozzles (batches 60 - 400 L)

Model 4600: 46" plate, 7 nozzles (batches 140 - 800 L)

By engineering each Wurster unit in-house, we ensure precision, reliability, and scalability. Our advanced solutions simplify transitions from R&D to commercial production or technical transfer, making Coating Place the trusted partner for fluid bed Wurster coating, regardless of project size.

The Original Wurster Technology Source

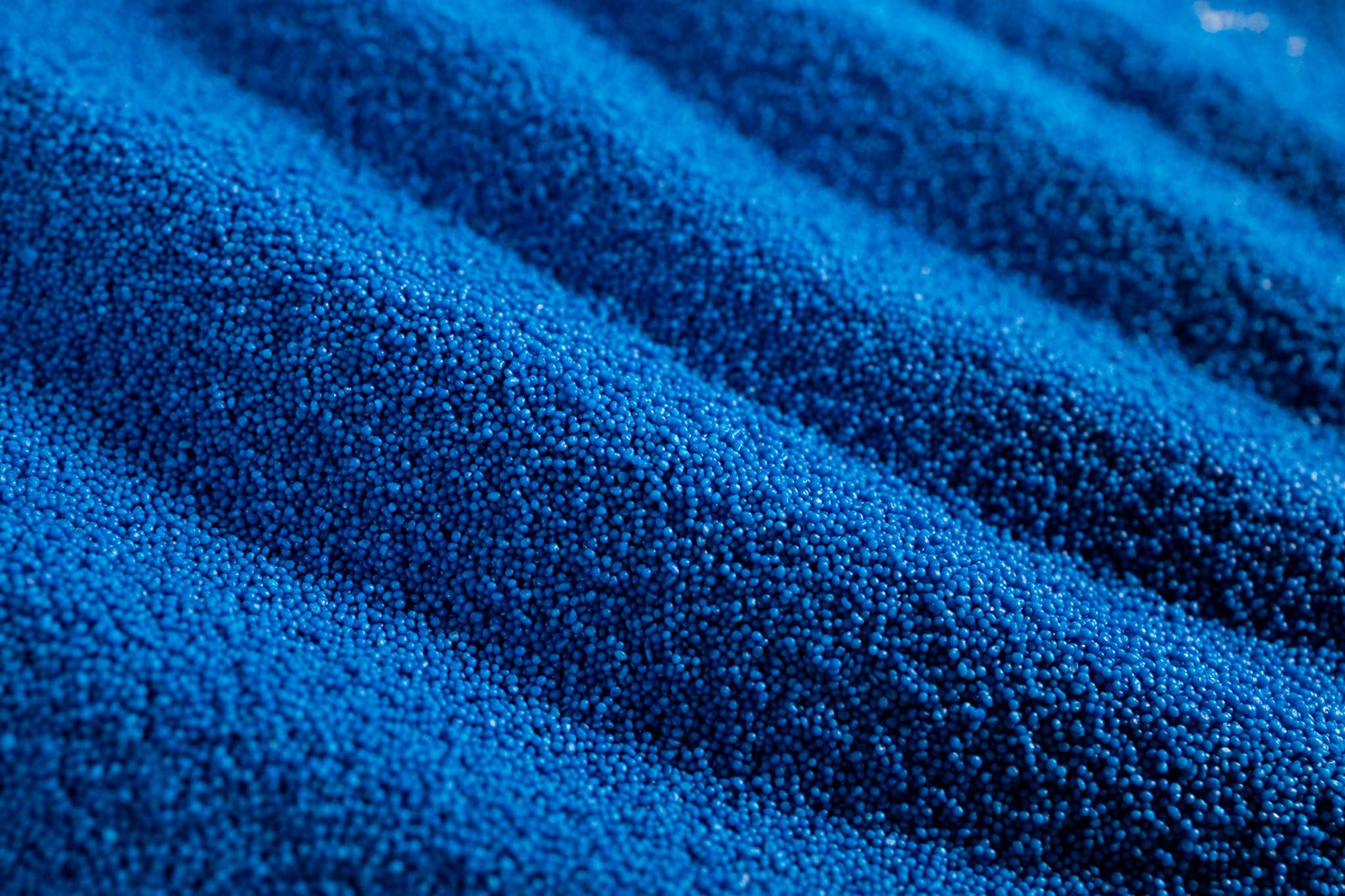

Since 1976, Coating Place, Inc. has been a leader in Wurster fluid bed coating, a process integral to fluid bed microencapsulation. This specialized method encapsulates particles in a fluidized bed using differential airflows to create efficient cyclic motion, enabling controlled, uniform coatings. The spray nozzle, positioned at the bottom of the bed, ensures precise application of coating material to individual particles while minimizing agglomeration. Layers are applied until the desired film properties are achieved.

Studies confirm that Wurster coating delivers superior quality and uniformity, minimizing material usage, reducing processing time, and adapting to a variety of core materials, particle sizes, and shapes. This technology can coat softgel capsules, powders, crystals, and granules, regardless of shape—spherical, crystalline, irregular, or amorphous.

Named after its inventor, Dr. Dale E. Wurster, this unparalleled technology continues to set industry standards. Coating Place is the only company offering services tied to Dr. Wurster’s original equipment design, combined with our proprietary linear scalability and formulation expertise. With modern facilities designed for product development, troubleshooting, and capacity expansion, Coating Place remains the premier partner for fluid bed microencapsulation.